Slaughter Line

Good yields start with high-quality live raw materials. Our main task is to protect high quality birds from farm to slaughtering. Slaughtering and defeathering are essential to obtain uniform high-quality carcasses. Every step from live bird handling, stunning, slaughtering, scalding to defeathering must be carefully controlled to avoid damage and product with bad quality.

-

Bird Unloading

Carry out a comprehensive inspection of all types of equipment required for unloading chickens, such as loading and unloading platforms, conveyor belts, chicken cage transporters, etc., to ensure that the equipment is in good operating condition.

-

Manual Bird Hanging

Workers take the birds out of the cages skillfully ensuring both feet of a bird are evenly hung on the hooks to prevent the falling or damage caused by uneven force.

-

Water Stunning

With specific voltage, current and frequency on the birds, normal electrical activity of its nervous system is interfered causing short-term coma and muscle relaxation to realize bird stunning.

-

Neck Cutting & Bleeding

Unilateral neck cutting: By precisely cutting the blood vessels on one side of the neck, usually the carotid artery and jugular vein, the chicken lose large amount of blood in short time and quickly enter in a coma achieving effective and efficient bleeding.

-

Scalding And Defeathering

With appropriate water temperature and timing, the adhesion between the feather and the carcass is reduced, making sure the easy and effective defeathering with intact carcass.

-

Foot Processing System

The complete foot processing system consists of foot unloading, foot scalding, foot deskinning, chilling, manual inspection and packing. Chicken feet with good quality are ready for local consumption or export.

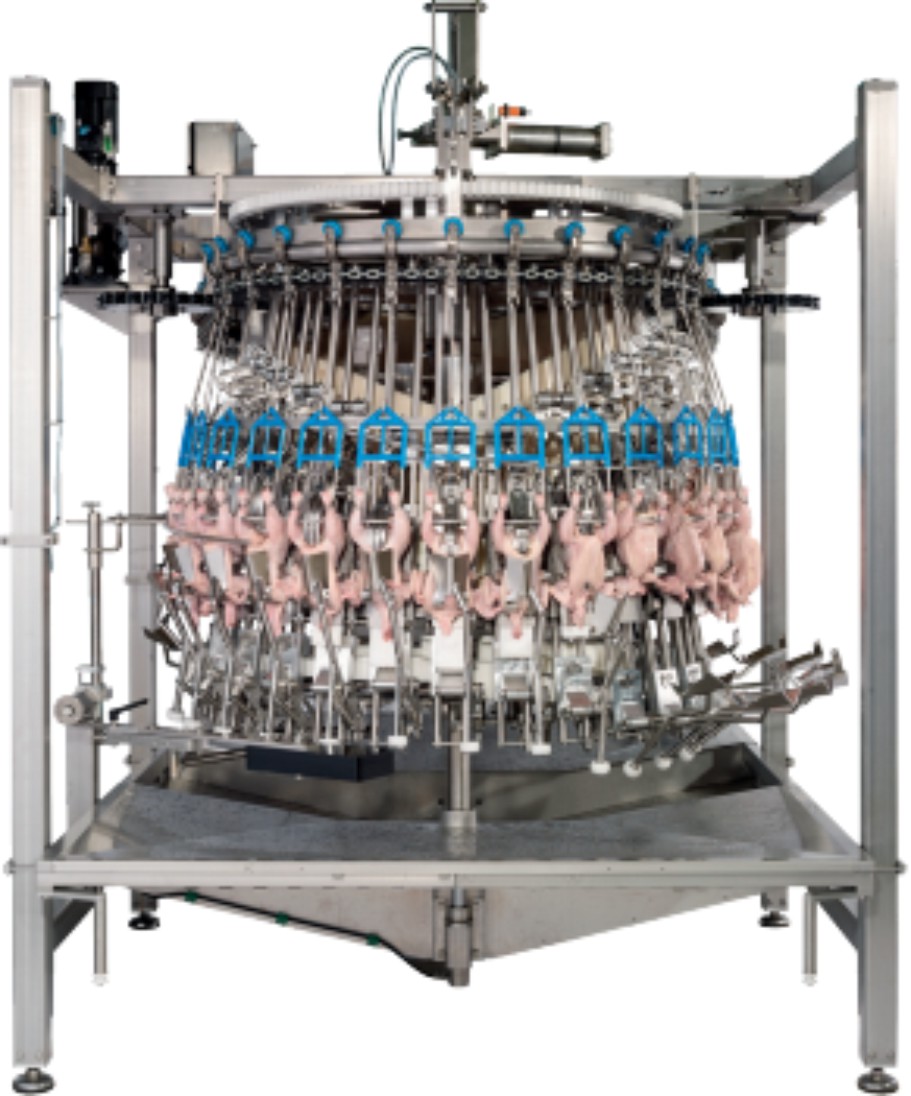

Efficient Evisceration System

Transporting live birds from the farm to the processing plant means moving the birds from a safe environment to new unfamiliar places. Animal welfare must be a main focus throughout bird handling, and environmental stress must be minimized during catching, transport, lairage and processing. What is good for animal welfare is also good for product quality.Good yields start with high-quality live raw materials. Our main task is to protect high quality birds from farm to slaughtering. Slaughtering and defeathering are essential to obtain uniform high-quality carcasses. Every step from live bird handling, stunning, slaughtering, scalding to defeathering must be carefully controlled to avoid damage and product with bad quality.Eviscerating is a core part in all the poultry processing plant. Birds after the evisceration are for direct sale or secondary processing. Purposes for the evisceration: to obtain Grade A carcasses for pre-chilling; to get the viscera for further processing and packaging.

Chonson Beyond can offer the automatic evisceration solution to deal with the challenges like carcass damage, cross contamination,labor efficiency and worker safety.

Our fully efficient eviscerating system can solve these problems and prepare the chicken for subsequent whole-bird packaging or portioning and deboning.

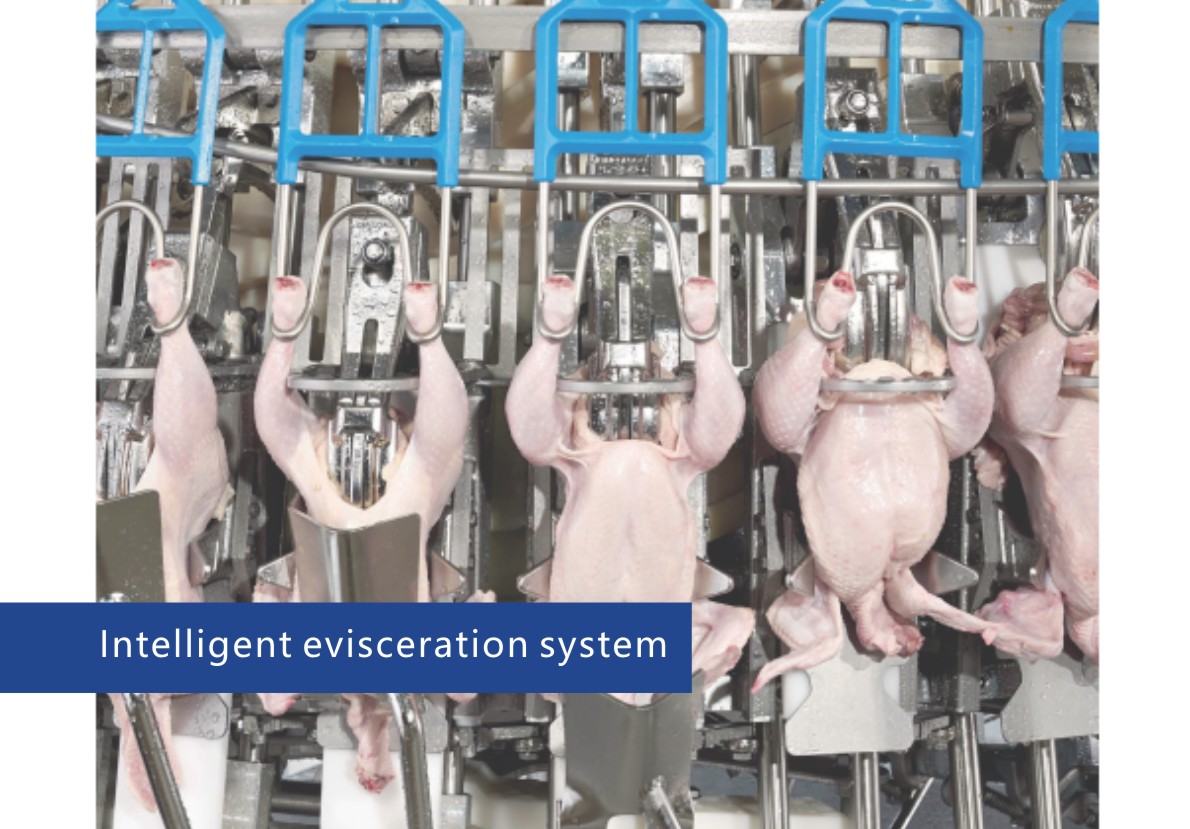

Intelligent evisceration system

□ Automatic venting □ Automatic opening □ Automatic evisceration □ Synchronous inspection □ Automatic crop removal □ Carcass internal and external cleaning

Automatic Venting

The vent cutter removes the vent by means of a circular cut. During the cut, the carcasses are held in a fixed position by special thigh clamps. Correct positioning is the key to an accurate cut. After the cut is made, the vent is removed from the carcass by vacuum and remains hanging next to the tail on the outside of the carcass. The vent cutter is equipped with knives of different sizes depending on the size of the carcasses.

For optimal positioning of the carcasses, the Vent Cutter 196 is equipped with a mechanical knife drive system and self-adjusting back clamps. The machine is also equipped with a tail puller to prevent the tail from being cut through when cutting the cloaca.

After the vent cutting, the Opener 246 cuts through the abdominal wall, from the cloaca to the tip of the keel bone, creating an opening for the insertion of the working element of the eviscerator.The carcasses are still held by the thigh clamps and stirrups in an optimal position for the cut. Correct positioning significantly reduces the risk of damage to the intestine.

Automatic Evisceration

The Eviscerator 218 automatically removes the giblets and rib cage in one block of viscera. The viscera block is transferred to a separate overhead conveyor and secured with a clip to eliminate the possibility of contamination of the carcass with fecal gut contents. Using this unique clip system increases the efficiency of block transfer.

Adjusting the eviscerator to the size of a particular batch allows for complete removal of the viscera block without damaging the intestines and rib cage, and minimizing contamination of the carcasses with bile or feces. For optimal viscera removal, the Eviscerator 218 is height adjustable and the evisceration spoons are available in several sizes. The machine is equipped with a quick release spoon, allowing for quick changeovers between batches. This flexibility allows the processor to supply from one line to several markets with different requirements, such as fast food, retail and deboned meat consumers.

Ensuring food safety

The block and carcass are synchronized for easy inspection, and the user-friendly overhead conveyor switch function allows the block and/or carcass to be dropped for more detailed inspection.

The overhead conveyor clip system positions the package for inspection in a convenient and easy-to-control manner, and prepares it for manual or automatic giblet sorting.

All inspection areas are equipped with emergency stop devices

Automatic Crop Remover

Automatic Internal And External Cleaning Of The Carcass

After evisceration, the 426 crop removal machine removes the crop and trachea from the bird's neck with a working element inserted into the abdominal cavity of the carcass.

The machine can be easily adjusted to various carcass sizes in a batch by adjusting the height of the main shaft with hydraulic power cylinders located outside the machine. Correct adjustment ensures proper positioning of the carcass and the working element. In turn, this again promotes effective removal of the crop and trachea without damaging the skin of the neck and breast.

It has been proven that external/internal carcass washing after evisceration reduces the amount of residues and bacterial populations on meat products.

The device for external/internal carcass washing/Inside-Outside Washer 494 thoroughly washes the carcass, removing dirt and bacteria on the internal and external surfaces of the carcass. Water nozzles are introduced into the carcass, washing the cavity, water flows out through the neck cut. From the outside, water jets wash the carcass from top to bottom.

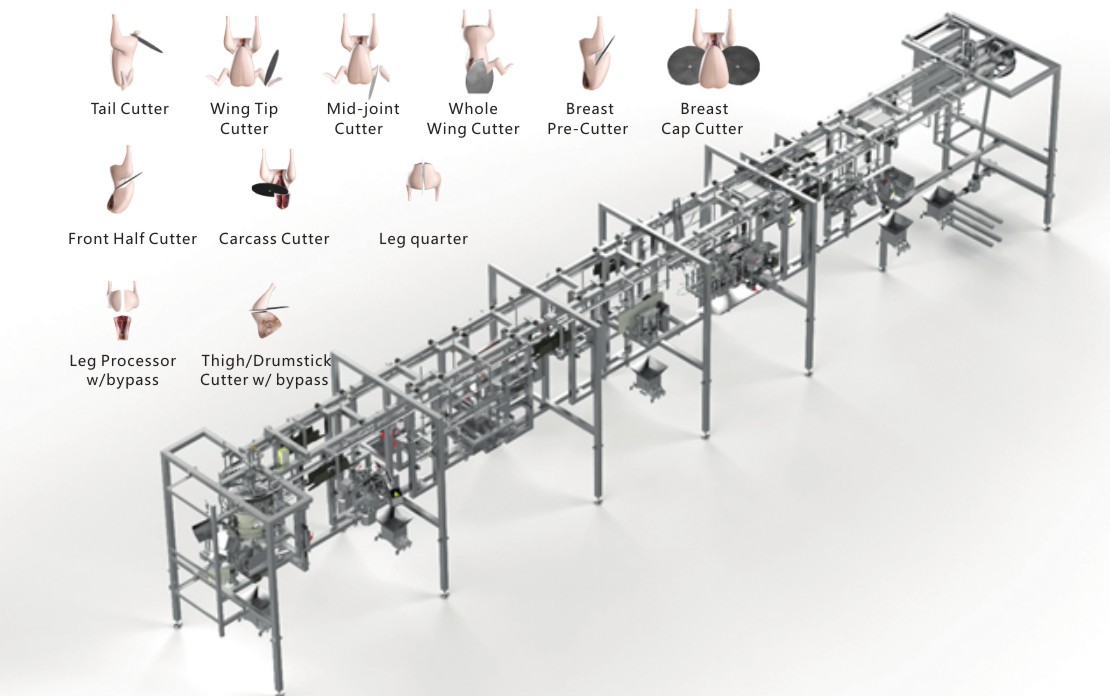

Automated Cutting Systems

The cut-up line performs reliable operation based on the set parameters, with precise cutting positions and uniform force.Ensure consistent separation for each piece of chicken; Reduce quality fluctuations in manual operations; Improve qualification rates.

Accurate cutting that comes close to hand cuts.By-passable cutting units to process various wing products on the same cut-up line.

The patented cutting allows for cutting one-winged birds and birds with broken wings in the optimal way.

Simple construction for easy maintenance and cleaning.

-

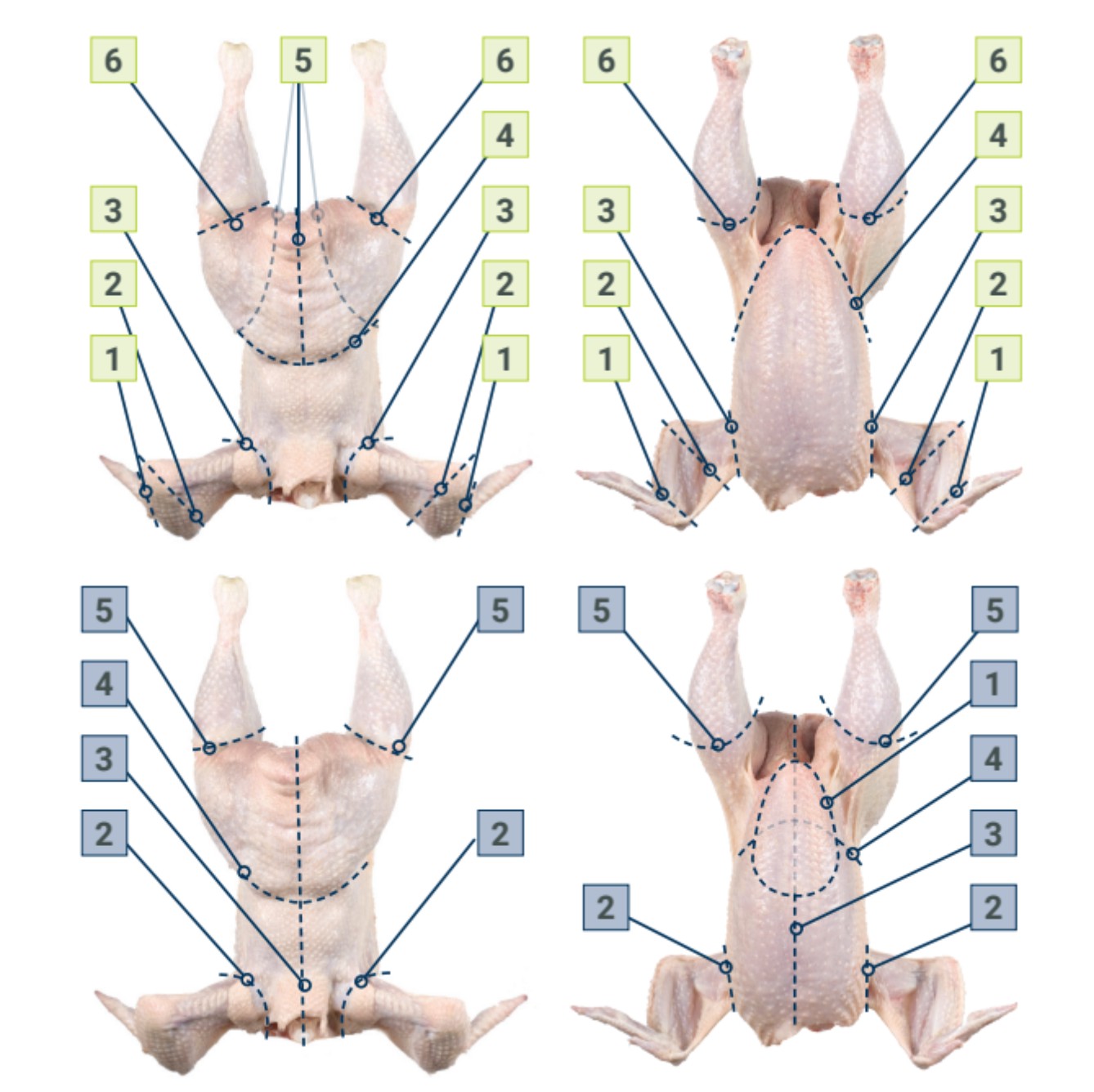

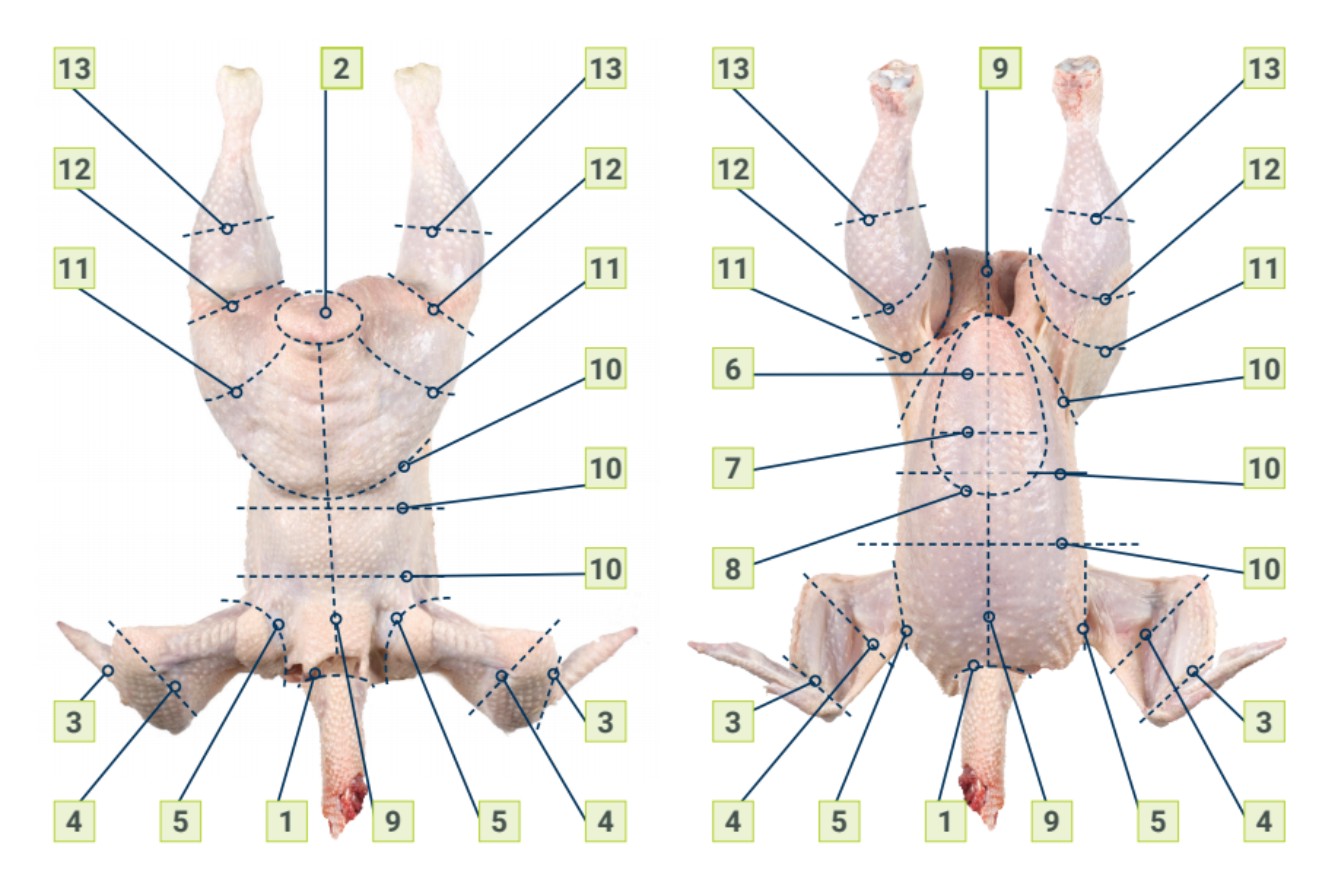

Anatomical and Clean Cutting

The ProFlex Premium system observes the well-established BAADER principles for clean cutting, flexibility and performance. Cut-up can be done in anatomical portions, e.g. 3-piece wing cuts and thigh/drumstick cuts. Following the cut-up, the individual pieces are automatically distributed to selected drop-off stations for batching, deboning, filleting or further processing.* -

Even Higher Capacity

The standard pitch is 12 inches, but if a higher capacity is needed, we have the option to use a 10-inch pitch. Using a 10-inch pitch means increasing the capacity of ProFlex Premium of up to 150 birds per minute / 9000 birds per hour. This option comes with a restriction because not all units fit the 10-inch pitch and need prequalification.

| Retail - 11 pieces | SplittingFood Service - 9 pieces | ||

| 1 | Wing tip cut | 1 | Keel cut |

| 2 | Mid-wing cut | 2 | Silver Dollar Wing cut |

| 3 | Anatomical wing cut | 3 | Vertical Splitter |

| 4 | Front half cut | 4 | Breast quarter |

| 5 | Either Saddle Splitter for leg quarter or Leg Processor for whole legs | 5 | Drumstick cut |

| 6 | Drumstick cut | ||

| Food Service - 25 pieces | Splitting | ||

| 1 | Neck cut | 1 | 6-piece breast cut |

| 2 | Tail cut | 2 | Thigh Halve |

| 3 | Wing tip cut | 3 | Drumstick cut |

| 4 | Mid-wing cut | 4 | Half drum cut |

| 5 | Anatomical wing cut | ||

| 6 | Keel cut 1 | ||

| 7 | Keel cut 2 | ||

| 8 | Keel cut 3 | ||

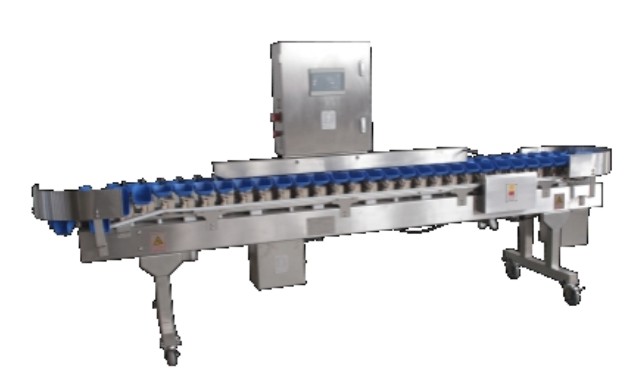

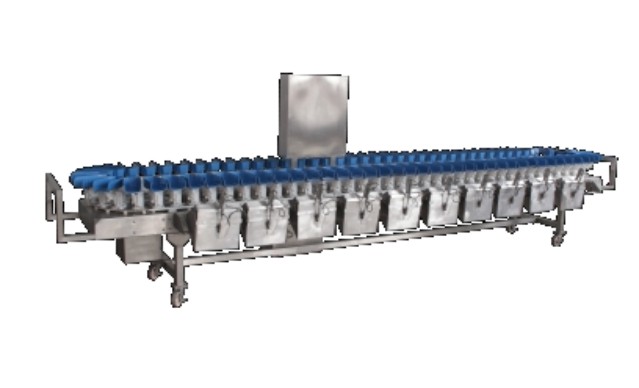

Grading

Plant profitability highly depends on accurate weighing and grading. Our graders are equipped with weighing decks with effective calibration methods for the accurate weighing result.

| Sorting Model | FJ-10J-500G-A | FJ-10J-700G-A | FJ-10J-1000G-A |

| 2 conveyor belts |

Chicken, duck by-products, poultry frozen products, wet sea cucumbers,

prawns, fish, etc., equipped with automatic feeding equipment.

|

Poultry products such as chicken breasts, whole chicken legs, frozen duck wings, aquatic products such as squid, fish, oysters, etc. are equipped with automatic feeding equipment. | Poultry chicken breasts, whole chicken legs, frozen duck wings, aquatic products such as squid, fish, oysters, etc., equipped with automatic feeding equipment. |

| Number of sorting levels | 5月21日 | 5月21日 | 5月21日 |

| Speed (per minute) | 280-310 | 240-310 | 240-310 |

| Sorting accuracy | 0.1g | 0.1g | 0.1g |

| Sorting error | ±0.5g-1g | ±1.5g | ±1g-2g |

| Size (length*width*height) |

(Level 5-7)3.4*1*1.6/(Level 8-10)4.2*1*1.6/

(Level 11-12) 4.5*1*1.6

(5-7级)3.4*1*1.6/(8-10级)4.2*1*1.6/

(11-12级)4.5*1*1.6

|

According to the on-site situation | (8-Level standard)5.3*1.2*1.65/depends on the site conditions |

| Power supply | 220V | 220V | 220V |

| Motor power | 200W-400W | 750W-1500W | 750W |

| Weighing system | IP69 | IP69 | IP69 |

| Material | SUS304 | SUS304 | SUS304 |

| Measuring range | 2g-500g | 100g-700g | 100g-1000g |

| Protection level | IP68/IP69K | IP68/IP69K | IP68/IP69K |

Conveyor

It is mainly composed of a power unit, a conveyor belt and various auxiliary devices. The power unit provides power to keep the belt running continuously and stably. The conveyor belt is made of food-grade material, such as food-grade plastic or stainless steel mesh belt, which ensures compliance with food safety and hygiene standards.

Belt conveyors are the most used conveying method in the food industry, including horizontal belt conveyor, inclining belt conveyor, vertical belt elevator, knife-edge belt conveyor, turning belt conveyor, etc. They can be used independently or in combination to realize automatic production.

Packaging

After the birds are processed, they will come into the packaging. With the vacuum operation, the machine can remove the air in the package, greatly slowing down the oxidation of the meat and preventing fat from rancidity; with the injection of inert gases such as nitrogen, a low-oxygen environment is created, inhibiting the growth of microorganisms and keeping the chicken in a good taste and flavor with the shelf life.

Automatic packaging machine with chain air conditioning

Product Description

Mainly used in chilled meat Applicable to the fresh meat field of medium and large food processing plants, fast speed, strong stability and high cost performance. Inherited line-joining mechanism, simple and efficient. Independently developed replacement patent technology, residual oxygen rate less than 0.5% super large mold, complete more packaging at one time. High-precision chain box feeding method is accurate and stable.

Technical features

1. Real-time fault reminder function.

2. Reminder for changing vacuum pump oil.

3. Packaging counting function.

4. Precise film feeding system.

5. Air pump drain reminder.

6. Tool-free mold structure replacement.

7. Optional fixed or adjustable gas mixer.

8. Simple operation, just one click and all packaging can be completed.

9. Millions of sliding without trouble, stable packaging.

Desktop Pneumatic Sealing Machine

Product Description

Desktop sealing machines are widely used in box packaging of cooked meat etc. Through sealed packaging, external air, moisture, microorganisms can be effectively blocked, slowing down the oxidation, and deterioration of the food.

Technical features

1. Pneumatic sealing, efficient and leak-proof.

2. Convenient box ejection.

3. Automatic film closure with cursor positioning,

4. Available for white and colored film.

Automatic chain skin packaging machine

Product Description

This machine is widely used in the packaging of chilled meat etc.

Excellent vacuum and body-fitting protection (extending the shelf life of products). PLC from Japanese Omron and HM interface are used for easy and reliable operation.

Technical features

1. Real-time fault reminder

2. Reminder for changing vacuum pump oil

3. Counting function

4. Accurate film feeding system.

5. Reminder for water discharge in the air pump .

6. Tool-free mold replacement.

7. Neat film cutting.